Every new Skoda vehicle begins as a concept, a vision crafted by designers and engineers. However, these ideas must eventually take physical form. This transformation happens inside one of the most tightly guarded areas of Skoda Auto’s Technical Development department: the secret model workshop.

The Heart of Skoda’s Future Designs

The latest creation from this workshop that the public is familiar with is the new Skoda Enyaq. The model workshop collaborates with various departments, producing multiple types of models for different purposes.

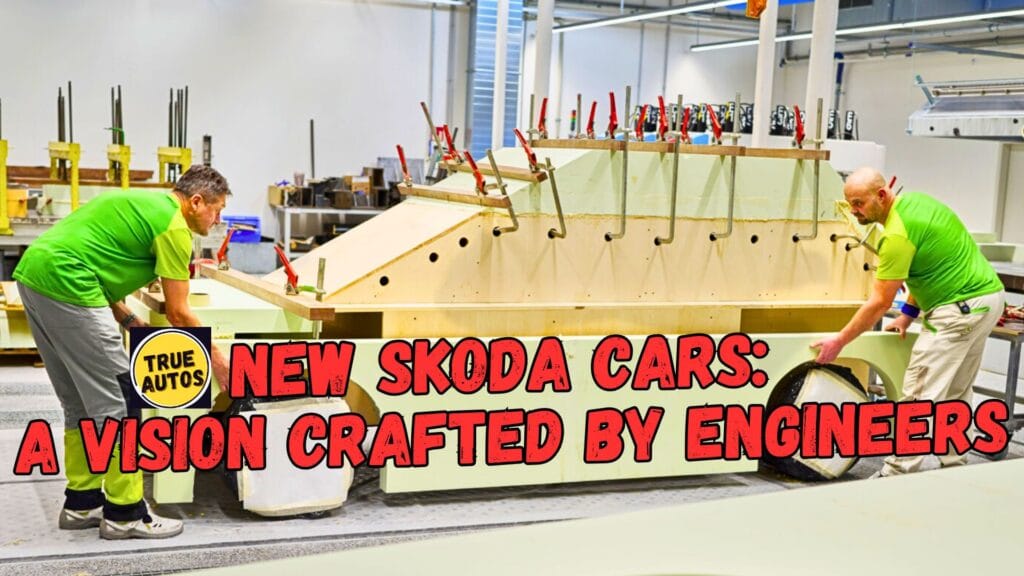

Building the Foundation: The Clay Model Base The foundation for clay models is constructed using a mix of steel, plywood, and polyurethane foam. This structure provides the base onto which designers apply the clay and sculpt the future car’s shape. These materials are stored in a specialized warehouse, 16 meters high, requiring precision handling by operators.

A Spectrum of Model Types

The workshop creates more than just clay models:

Hard Models: Made of solid materials, these models do not undergo significant shape changes.

Ergonomic Interior Models: Used to test accessibility and interior space.

Proportion Models: Carved from polyurethane foam to assess overall design.

Color and Material Models: Used to evaluate interior trim options.

Aerodynamic Models: Built for wind tunnel testing, requiring quick part swaps while maintaining structural integrity.

Control Models: Two highly precise models, FKM (for surface control) and DKM (for CAD data control), ensure production accuracy within millimeter tolerances.

Precision and Advanced Technology

To achieve high accuracy, the workshop has dedicated measurement centers. Advanced 3D printing is used for intricate parts such as headlight components, which are later polished and painted to match the final production look. The workshop also includes a metalworking division capable of machining engine blocks and prototype parts for testing. Some parts even support Skoda Motorsport’s development efforts.

Craftsmanship and Collaboration

With around 80 specialists, including programmers, machinists, designers, and technologists, the workshop is a hub of interdisciplinary cooperation. One of the most intricate models crafted recently is the Enyaq, presented in the stunning Olibo Green metallic finish. The workshop ensures that every detail, from panel gaps to material textures, meets Skoda’s rigorous standards.

Where Ideas Become Reality

While the work in the model workshop may seem like a mix of sculpture and engineering, precision is paramount. Every prototype undergoes meticulous assembly, measurement, finishing, and reassembly. This is where multiple departments unite to create vehicles that will soon be seen on roads worldwide.

By bridging digital design with physical reality, the model workshop plays a crucial role in shaping Skoda’s future lineup, proving that innovation and craftsmanship go hand in hand.